This is EnkaFusion

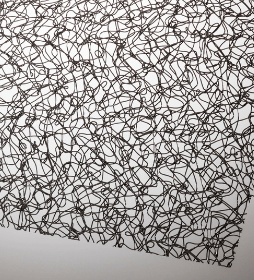

Enka-Fusion flow media are flexible mattings, produced from polyamide, polyester or polypropylene monofilaments. These are thermally bonded together where they cross to form a flexible, yet compression resistant matrix with over 95 % of void space.

Enka-Fusion flow media are flexible mattings, produced from polyamide, polyester or polypropylene monofilaments. These are thermally bonded together where they cross to form a flexible, yet compression resistant matrix with over 95 % of void space.

The Enka-Fusion product portfolio includes two categories of flow media: in addition to two-dimensional variants with randomly laid monofilaments, three-dimensional mattings with a v-shape filament configuration are also available. EnkaFusion can be easily cut to suit different infusion mold sizes.

Thanks to the comprehensive width and depth of the EnkaFusion assortment, the right product variant can always be offered to meet specific requirements. For example with regards to tensile strength, flow rate or compressibility.

How EnkaFusion is used in vacuum infusion processes

In most processes, EnkaFusion is installed between the vacuum bag and the peel ply. It helps resin to travel freely and permits a complete wet-out. EnkaFusion is the fastest resin transfer medium available in the market today and a versatile solution to increase mold efficiency. Thanks to its unique structure, EnkaFusion allows continuous flow in x, y as well as z directions. This way, the product not only facilitates fast resin flow. It also ensures its uniform distribution into all edges of the laminate. And that without leaving any imprints on the surface of the finished product. One single person can handle adding EnkaFusion to the lay-up. EnkaFusion cuts easily with a pair of scissors. And it is flexible enough to conform to any surface and geometry. Therefore, installing custom pieces is simple and quick. The matting is compatible with many resins, from polyester to epoxy.

EnkaFusion resin transfer media are often applied in combination with an EnkaChannel resin feeder.

What makes EnkaFusion the ideal resin transfer medium?

Features:

- 95 % of void space

- Compression resistant

- Lays flat (does not curl or twist)

- Compatible with all resin recipes

- Resistant to chemicals

- Lightweight

Benefits:

- Simple to cut and shape

- Easy to fix in the mold

- Minimizes set-up time

- Maximizes flow rates

- Ensures complete and even coverage of resin

- Minimizes infusion times, thus optimizing process efficiency

- Americas

- Asia Pacific

- Europe, Middle East & Africa

-

Consumables for resin infusion processesENKA®CHANNEL & ENKA®SPACERpdf 1MB

-

Spacer for reaction injection moulding processesENKA®SPACERpdf 2MB

-

Flow media and spacers for vacuum infusion and structural injection moulding[NEW] Solutions Overviewpdf 3mb